Heat pump basics

Heat pump basics – there are a few different types of heat pump available but we will concentrate on the most commonly fitted examples, air source and ground source.

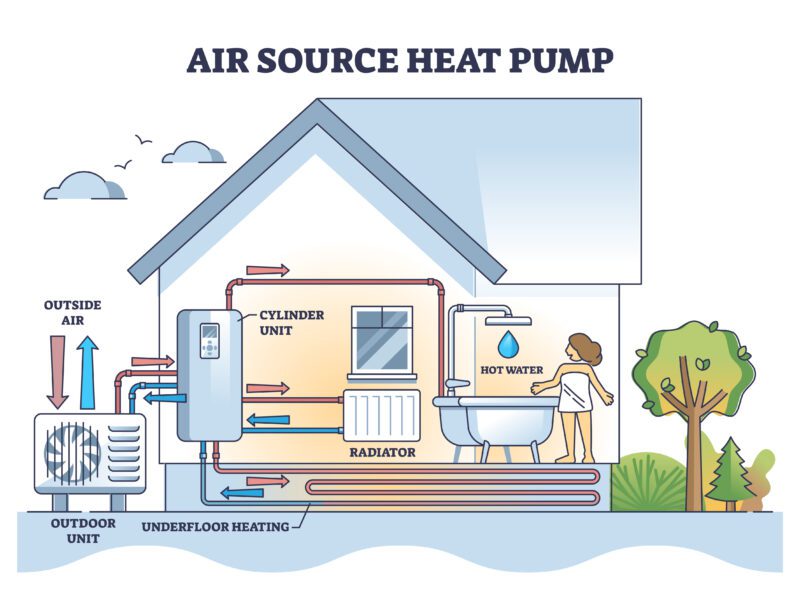

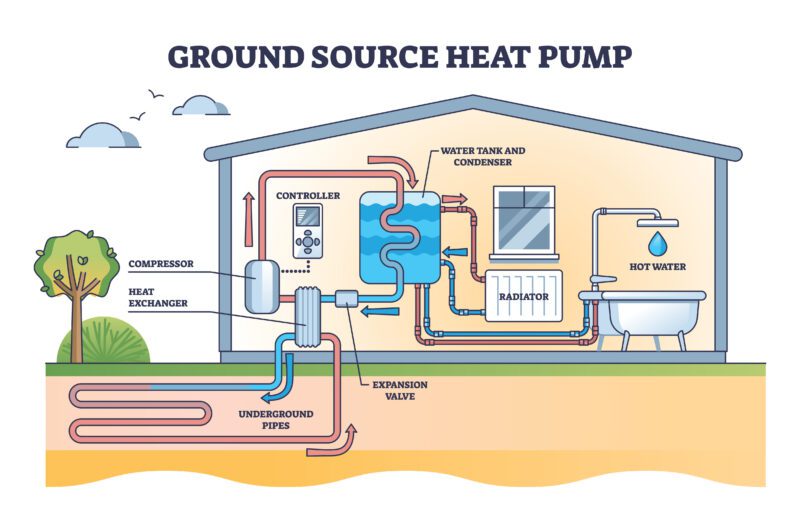

All heat pumps work by extracting free heat from their surroundings, via a fan / impeller (air source) or a buried system of pipework (ground source). The collected heat is then stored in a closed loop of liquid refrigerant that turns into a gas as it warms. This gas is then highly compressed, boosting the temperature further.

The hot gas is passed through a heat exchanger surrounded by cool water, the cool water is now heated by the gas and fed to your heating system, whilst the gases condense back into a liquid, ready to start the process all over again.

Air source heat pumps

The heat exchanger can also be surrounded by cool air, which is then heated and released via a system of ducts, similar to an air conditioning unit. The similarity doesn’t end there as it can also offer space cooling.

This type of heat pump is known as ‘air to air’, but the ‘air to water’ type is by far the more common, being, as it is, a direct replacement for the tried and trusted ‘wet heating system’ i.e. boiler, heat emitters (such as radiators) and provision of hot water.

Ground source

Whilst an air source heat pump gathers latent heat from the air surrounding it, a ground source pump works, as the name implies, by extracting the heat found below ground, via a coiled system of pipework laid horizontally, or vertically, via boreholes.

They are more efficient than air source – the UK ground temperature 2 metres below ground is a steady 8 – 11 degrees – meaning that less power is required to boost the temperature to a point where it can provide space / water heating.

However, this efficiency gain comes with a financial penalty: they are far more expensive to install than their air source counterparts, mostly due to the groundworks required. You must also have a garden big enough for the pipe run or to allow access for drilling machinery, should you decide to ‘go vertical’.

Efficiency of heat pumps

The reason why air pumps are considered so energy efficient is because they typically produce 3 – 4 units of power for every unit of power consumed. This is known as the ‘coefficient of performance’ (COP). Most models in the UK are measured running at an average COP of 3.2, so put very crudely, if you put in 1p’s worth of energy, you actually get 3.2p’s worth of energy out.

Also, as opposed to generating heat – like a boiler would by burning gas – a heat pump actually takes pre-existing heat and ‘concentrates’ it. Furthermore, as the electricity grid continues to be decarbonised by using more renewable sources of energy such as wind, solar and tidal, the green credentials of the heat pump become increasingly hard to ignore.

Note- a behavioural shift is needed!

Whilst the technology is in itself a great leap forward, it does also require a big behavioural shift on behalf of householders. Instead of putting the heating on when you feel cold, turning up the thermostat when the temperature drops further and expecting rapid temperature change, a heat pump performs at its most effective when running nearly constantly at a far lower temperature, providing you with a constant source of ambient heat, that can be slowly increased when required.

With this in mind, you will be best served by a heat pump if your house is thermally efficient, ie the building fabric retains heat instead of losing it rapidly. If the latter is the case, your heat pump has to work harder to supply the extra heat, losing efficiency and proving more costly to run. Look into fitting some additional insulation at your property, or at the very least, make sure your draught-proofing is up to the job – your heat pump and pocket will thank you.

Will I need new radiators?

Some consideration should be given to how you are going to emit the heat from the pump. In an average gas-fired central heating system the water in the radiators will be 70 degrees celsius +, in an heat pump based system it could be around half that, meaning radiators will feel warm, not hot, to the touch.

There are numerous scare stories around having to replace all your radiators with far larger models to effectively generate the lesser amount of heat. This simply isn’t true as many existing radiators are up to the task, although smaller, single panel radiators would probably require replacing.

If you have reasonably sized two panel, two convector (two sets of ‘fins’ between the panels) radiators, then, in all likelihood you’ll be fine. A competent installer will also be able to repurpose existing radiators in other rooms should you only need a couple upgrading.

It is worth remembering that an existing radiator can be replaced with a wider (3 panel) radiator, with or without convector fins, that will fit to the existing pipework.

Sadly, cast iron radiators, whilst looking beautiful, are really not suited to heat pumps – the density of the material makes it difficult for the lower temperature to penetrate through and warm the surrounding air. A cheaper, thin steel radiator with a large surface area is the optimum emitter.

Going underground

Underfloor heating is also suited to a heat pump setup but is not an essential requirement. As it was originally designed to work at a lower temperature it can be a good fit for a higher temperature heat pump.

If you’re considering having underfloor heating installed, ensure it is heat pump ready, this means the installer will space the coils more closely together than the traditional layout. This increases the surface area, and thus, the amount of heat that can be emitted.

In hot water

If you are thinking of having your combi-boiler replaced with a heat pump then a major consideration will be hot water provision. Due to the way a heat pump operates (slow, steady and cooler), it is entirely unsuited to providing piping hot water on demand and instead relies on a large (170 litre plus) insulated cylinder in which to store the hot water it produces.

Again, this water will be cooler than what you are used to, meaning you probably wouldn’t be adding cold water when running a bath, for example. The hot water cylinder will also contain an immersion heater so it can also be run ‘standalone’. If you already have a fairly modern large hot water cylinder then you may well be okay, however, if you have a smaller, older cylinder or don’t have one at all, some thought will have to be given to where this can be located.

What’s in the box?

Kit wise, the most common ‘monobloc’ heat pump system will consist of an outside unit, around the size of an air-conditioning unit, that houses the evaporator and the condenser, plus a control unit and hot water cylinder inside the house.

A ‘split’ system has the evaporator outside whilst a condenser + controller unit and the hot water cylinder are all in the house. Finally, a ‘packaged’ system again houses the evaporator externally, whilst the control unit is inside connected to a combined condenser / hot water cylinder unit, the size of a large fridge.

There are various factors that may influence your decision including inside / outside space, noise considerations and obviously, budget – a good installer will listen to your requirements and be able to advise on the most suitable system for your dwelling.

Will it disturb the neighbours?

Obviously this is model dependent, however most heat pumps run at around 40-60 decibels – somewhere between a fridge and normal conversation level. A lawnmower, for comparison, is around 90 decibels.

How much do heat pump systems cost?

At the time of writing, costs for an air source heat pump, including installation, are anywhere from £5,000 – £18,000, with ground source being around £10 – 25,000+. Payback time is over the lifetime of the heat pump, which should be around 15-20 years.

To encourage take up, and offset the initially high purchase price of a heat pump, the Government’s Boiler Upgrade Scheme is now open for applications. The scheme is due to run until 2025 (alongside a 0% VAT rate) and offers households or businesses a one-off grant of £5,000 / £6,000 towards the cost of purchase and installation of an air source or ground source heat pump respectively.

Running costs were traditionally the same as a gas boiler, however, this was before the fuel crisis and wildly fluctuating costs. Every house will be different and costs can vary significantly. A simple rule of thumb is the smaller the heat pump, the less hard it has to work, the more efficient it is and the cheaper it will be to run

Further information / installers

Use your favoured search engine: a wealth of resources and installers await on the internet. Do your homework, check the reviews and ensure your chosen installer completes a thorough pre-installation survey of your home to advise on the right pump for you – too big an output pump having to turn off and on regularly will be as inefficient as too small a pump working too hard. All heat pump installers must be MCS (Microgeneration Certification Scheme) certified. Click here to see if a heat pump is suitable for your home.

For potential ways to fund heat pump installations see here for green mortgages.