How green is electric car production?

Though large amounts of resources are used in making electric cars and driving them, most of it stays in use for the life of the vehicle.

Crude oil by contrast is only used once in a fossil fuelled car, and much of this ends up in the atmosphere, unlike electric car components.

The production of a fossil fuelled vehicle takes fewer resources. But it then produces far more pollution in its lifetime than the EV.

Energy is the single dirtiest part of battery production, as the world cleans up its act and moves away from fossil fuel to renewable energy production, so electric cars will be greener. Though we aren’t moving quickly enough, we are at least moving. As the energy transition gathers pace electric cars will become less impactful on the environment.

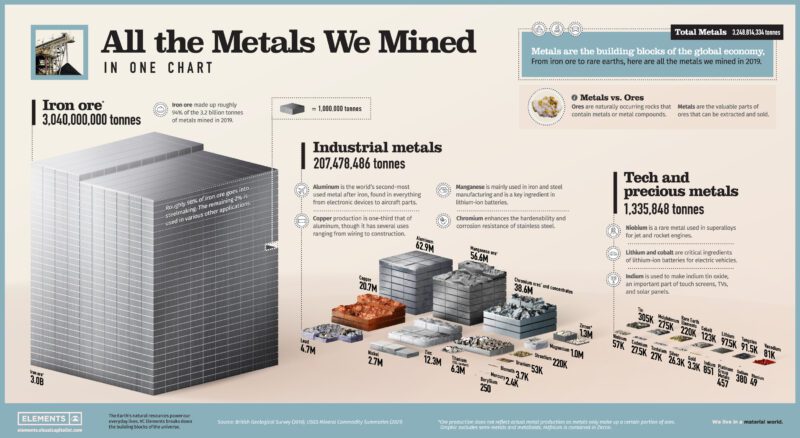

Mining of lithium and cobalt is negative but we need context

Many of the minerals needed for EVs come from countries with poor environmental protections and working conditions. But it would be wrong to focus on cobalt and lithium mining whilst ignoring the rest of metal mining that is not cobalt or lithium. See below for the great pic from the visual capitalist.

That’s not to say EVs don’t need to improve their supply chains and minimise the impact from mining and production – they do. But it shouldn’t be used as a stick to beat the EV market up with.

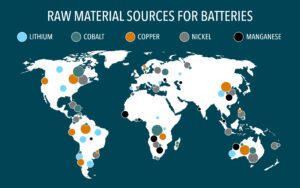

What minerals are needed for EVs and from where

There are largely two battery chemistries that you will likely run into.

- Nickel manganese cobalt (NMC) battery contains a cathode with nickel, manganese and cobalt as well as lithium and graphite.

- LFP, lithium iron-phosphate as well as an anode of graphite.

- In both, copper wiring connecting the cells as well as plastic and other less expensive materials.

Cobalt

Over 70% of the world’s cobalt comes from the Democratic Republic of Congo (DRC), one of the poorest countries in the world with highly questionable human rights records, see more detail from the Independent.

The average average income in the country is just £800 a year. Some 90% of cobalt is mined by global mining companies that strip-mine large parts of the DRC’s lands for their ores. Strip-mining involves taking all the topsoil and vegetation off the surface and destroying rainforest and other ecosystems.

The global mining companies present themselves as the ‘good guys’. Smaller mining companies are known to use children as young as 7 years old to extract the ores from the ground amongst other human rights abuses. How green are electric cars with this devastation and exploitation?

Nickel

Tesla has recently paid for exclusive access to mines in Indonesia. Indonesia is one of four global centres of nickel extraction.

Russia, China and Canada are the three best locations for nickel mining. Russia is engaged in the Ukraine war. China is well known for its human rights violations. That leaves Canada, which exploits ecologically fragile Arctic tundra by strip-mining for the metal.

Lithium

One third of the world’s lithium salts come from arid areas of South America. Despite the regions being dry, they use a lot of fresh water to extract the salts and then ship the lithium ores abroad to be processed.

China and Australia also have significant resources. These countries use heat from energy sources like coal to extract the lithium ores, which is harmful to the climate.

Iron, Copper and Other Elements

Copper is used in all batteries and electronics. This is often strip-mined, as is iron. They are relatively benign compared to cobalt and lithium. Ultimately we need to ask ourselves if we need to consume so much as such massive resources would not be required.

Energy use in mining and production

To dig up and turn the ores and salts into metals to make batteries takes a lot of energy. This is the most harmful aspect of battery production.

Battery production is a significant part of the overall CO2 emissions of an EV in its lifetime.

A complication is the energy mix of the electricity used to power an electric vehicle. The EU centre of battery production Poland is a coal based energy user. Should Poland use wind and solar more, so battery production would be greener.

Globally, China is the world’s biggest producer of EVs yet has a very dirty energy mix. Cars then have to be transported thousands of miles to European and US markets.

The Ethical Supply Chain

Where it comes to how green electric cars can be, this is down to an ethical supply chain. The race is on to find a greener battery that produces sufficient energy density. For example, greener, sodium-ion batteries (instead of lithium-ion) are in production but are far less energy dense.

One of the big reasons that Tesla CEO Elon Musk has pushed lithium ferro-phosphate (LFP) batteries for many of the vehicles he produces is that it is a cobalt free battery.

However, LFP batteries lack the energy density or performance of nickel manganese cobalt (NMC) batteries. He has pushed the search for batteries using minimal amounts of cobalt for his NMC powered vehicles, and the quantities of cobalt in batteries have fallen considerably over the years as a result.

There are ways forward where it comes to improving the supply chain and this involves something that can be done everywhere in the world – reuse and recycling.

Advancement in chemistries are helping

In the last 5-10 years we have seen huge advances in battery technology. Ten years ago:

- No car could do 1000km per charge – several do today

- LFP batteries weren’t possible due to energy density

- Solid state batteries were just a fantasy

A solid state battery has a solid electrolyte barrier between a reactive anode and cathode that cannot explode. It could be charged much more quickly and have far higher energy density than any other chemistry. No cobalt is required to make them too. We will see these soon.

Find out more on EV battery efficiency.

Reuse and recycling

Reuse

Reuse of batteries at the end of their lives is far more planet friendly than recycling. Reusing EV battery modules and cells at the end of their lives in the car can already be done today. Used EV batteries are stacked in containers and used as grid electricity storage. Grid batteries further reduce our reliance on fossil fuels.

Recycling

Crushing up, shredding and boiling the old batteries before extracting the metals takes a lot of energy in its own right. This is why reuse is better than recycling.

With millions of EVs on the road there are millions of tonnes of expensive metals in these vehicles that can be taken out and recycled.

There are ethical and environmental problems with battery recycling.

- Packaging of the batteries is often incinerated or goes to landfill.

- Some companies claim that they have extremely high rates of extraction of things like lithium, nickel and cobalt in their recycling processes,

- Other companies aren’t achieving anything close.

That we aren’t seeing EV manufacturers announcing they are using recycled batteries in their vehicles in their Environmental, Social and Governance (ESG) reports suggests we aren’t there yet.